Rx for Low Process Efficiency

News: SPI exhibited at the 2018 SPE Improved Oil Recovery Symposium in Tulsa OK.

News: SPE179615MS paper and presentation are given in the Document/Reports tab

Background

SPI Technologies LLC was formed in 2009 to address the sealing needs of industry utilizing SPI Gel Technology. The company is a wholly owned subsidiary of Impact Technologies LLC, located in Tulsa, Oklahoma.

SPI is the acronym for Silicate Polymer Initiator. SPI gels are an environmentally friendly, multi-component, silicate based systems that pumps like water and sets into a gel that is 4 to 10+ time stronger than any cross-linked polyacrylamide systems (sl-PAM). Both external and internal initiators can be used to set the SPI gel system.

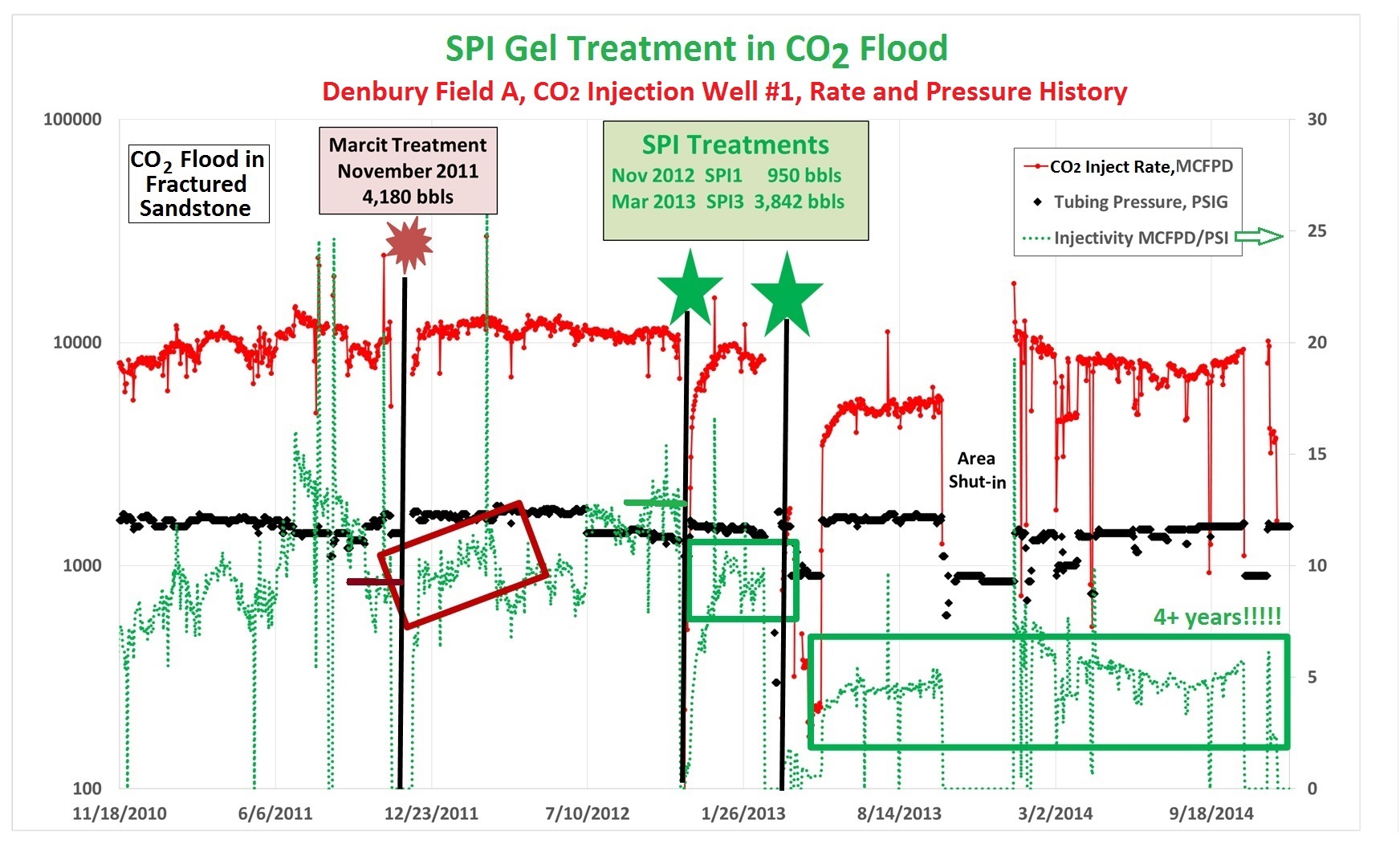

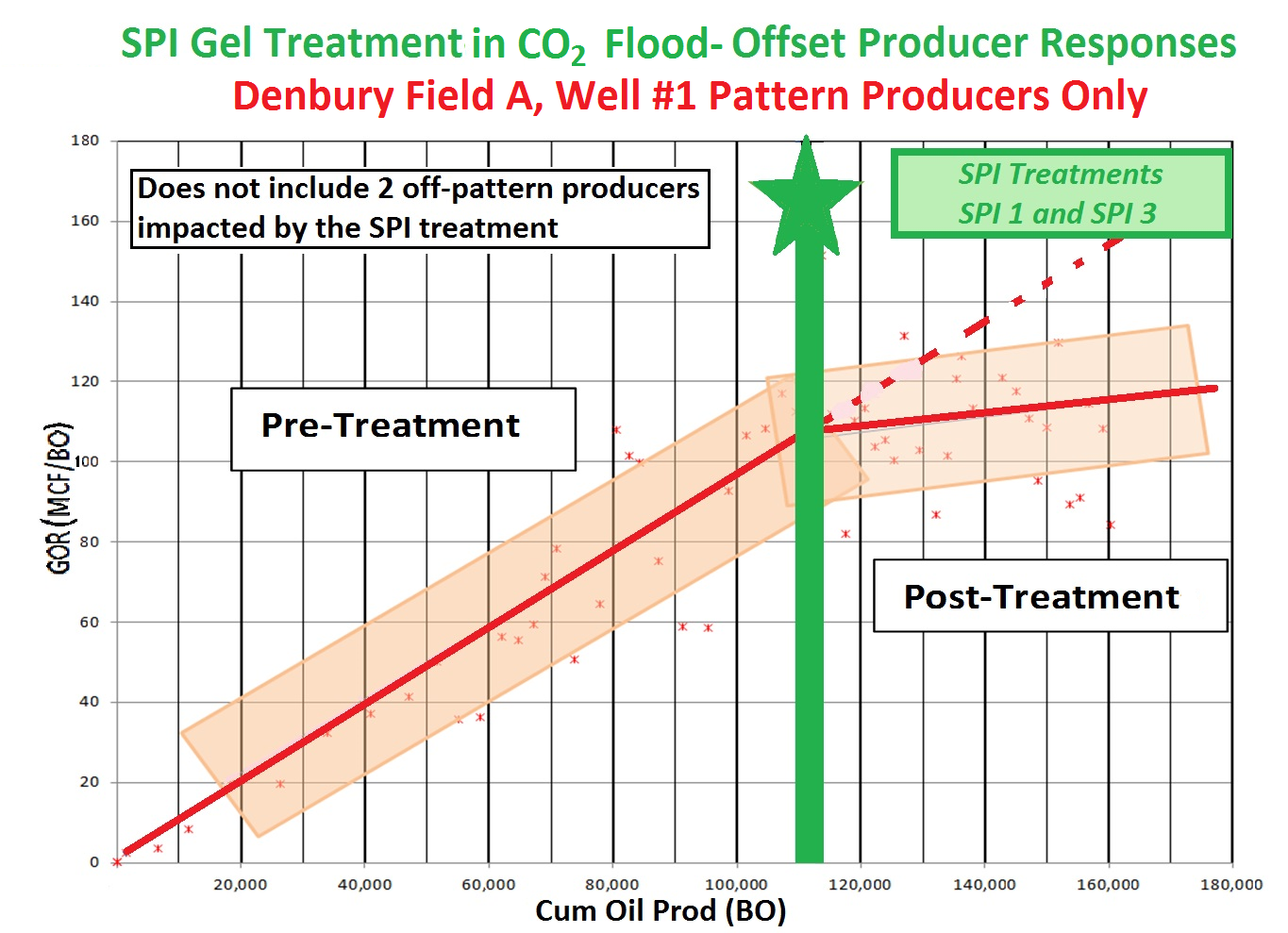

SPI gels have applications in carbon dioxide (CO2) floods (oilfield EOR and sequestration/storage), waterfloods (oilfield), production well casing leaks (oilfield), sealing off problem zones while drilling (oilfield), cement plugging of wells (oilfield), basement sealing (residential and commercial building / home), and tested in other applications.

SPI gels can be formulated for specific sealing applications. While utilizing the internal or external initiators to delay-form light gels up to paste-like gel products, they have been field demonstrated to perform where PAM systems DID / COULD NOT perform. SPI gels are not as strong as cements or epoxies, but can enter pores and other flow paths where cements cannot and can also be water or chemical jetted / cleaned out as needed. SPI gels have superior placement capabilities that other sealing systems do not possess. SPI gels are environmentally friendly and contain no heavy metal initiators. High temperature SPI gel formulations have also been prepared and are under development.

SPI gel development started in 2004 by Impact Technologies LLC, RTA Laboratory and Clean Tech Innovations LLC. The base technology is patented under United States Patent (USPTO) No. 882238 with additional patents-pending in the US and internationally. Development and field testing was aided by The Stripper Well Consortium (SWC), Oklahoma Center for the Advancement of Science and Technology (OCAST), the Department of Energy (DOE) and many industry partners.